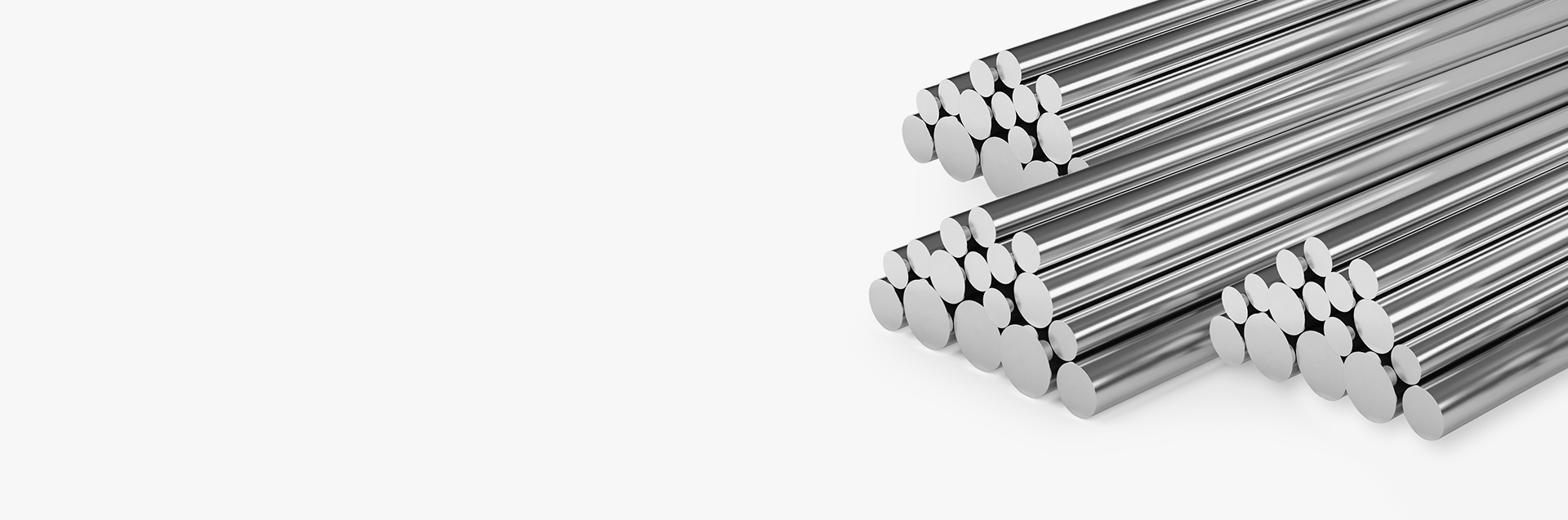

We have perfected over 450 grades of alloy steel products that exceed even the most demanding international customer specifications through in-house research, global benchmarking, and a kaizen approach to internal processes. Find out more, by visiting Mukand Sumi.

With the merger of Sumitomo Corporation and Jamnalal Sons (P) Ltd., we are one of the most well-respected alloy steel manufacturers in the country, with speciality, long steel products for almost every industry.

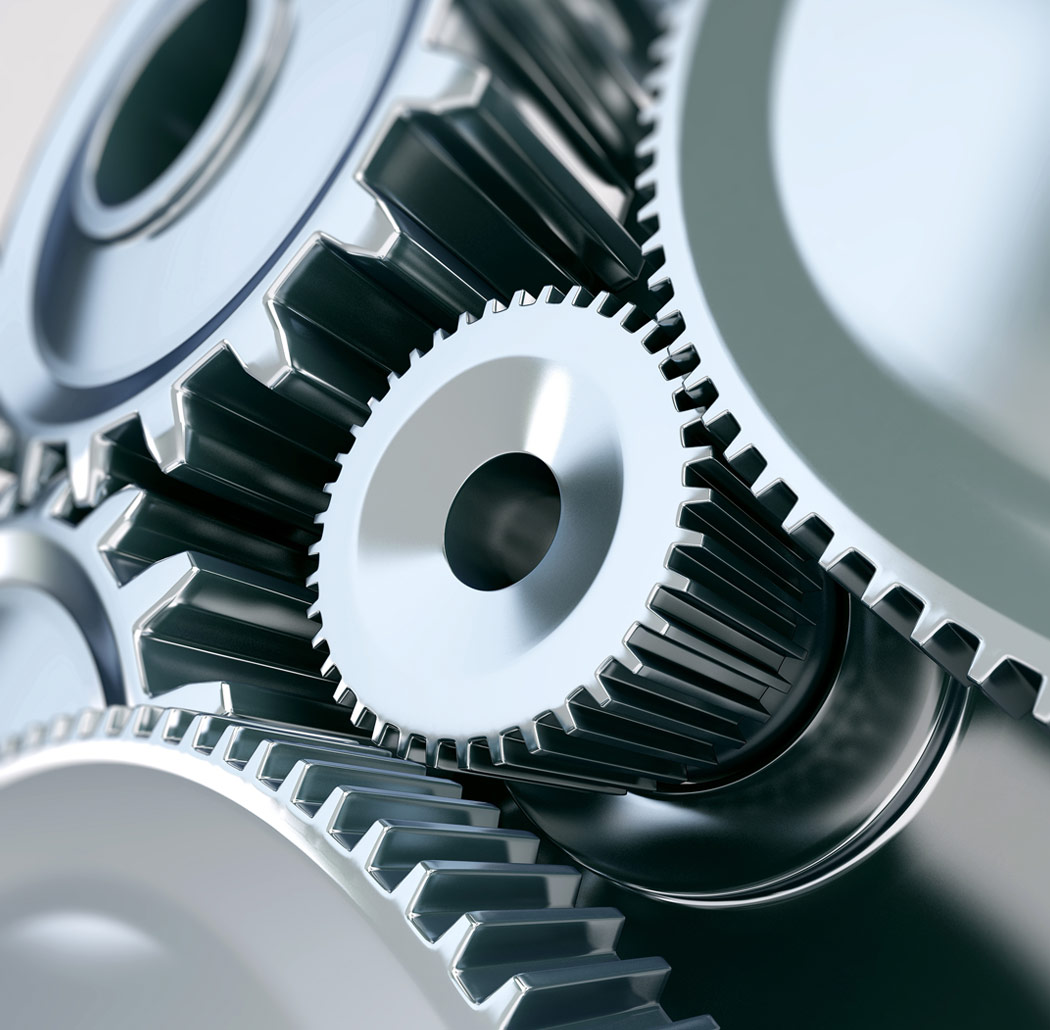

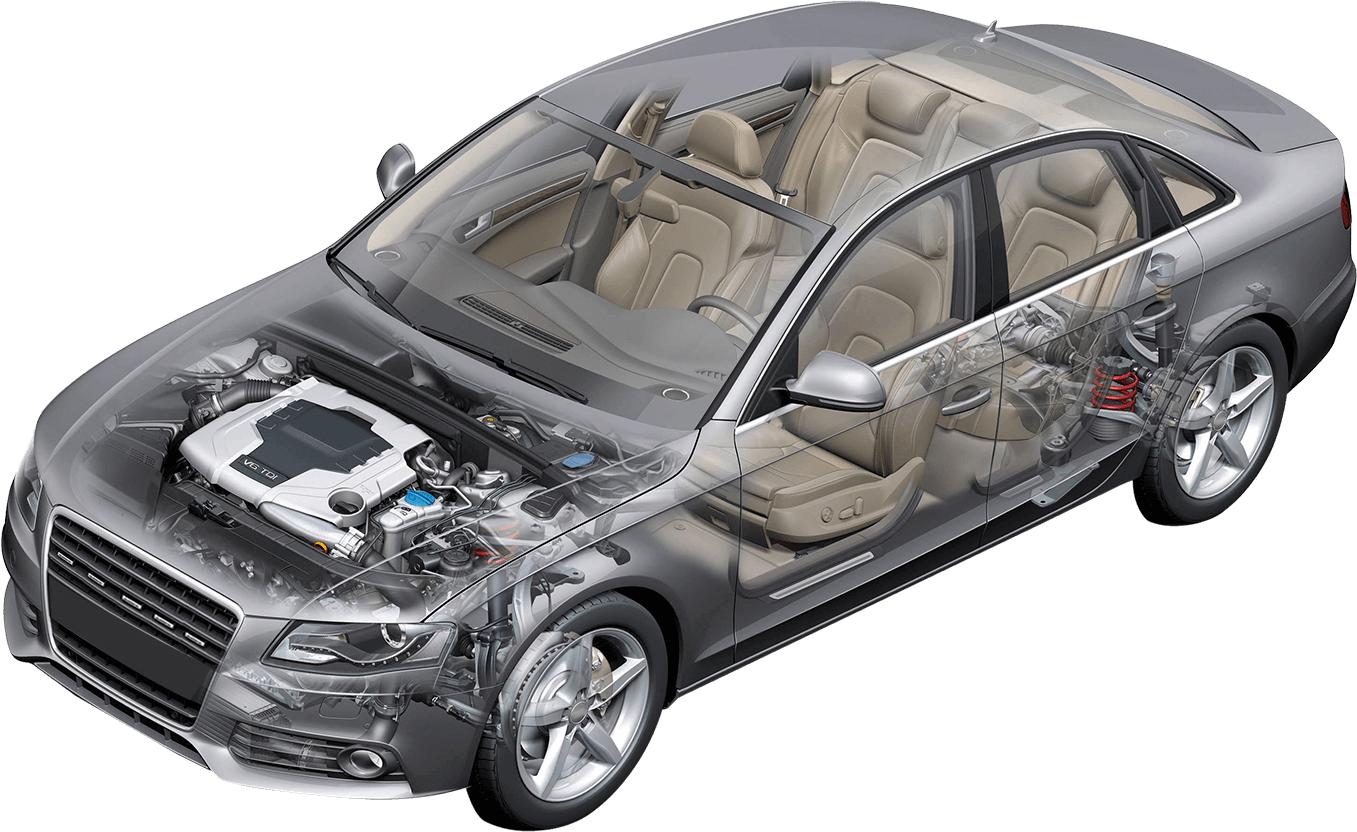

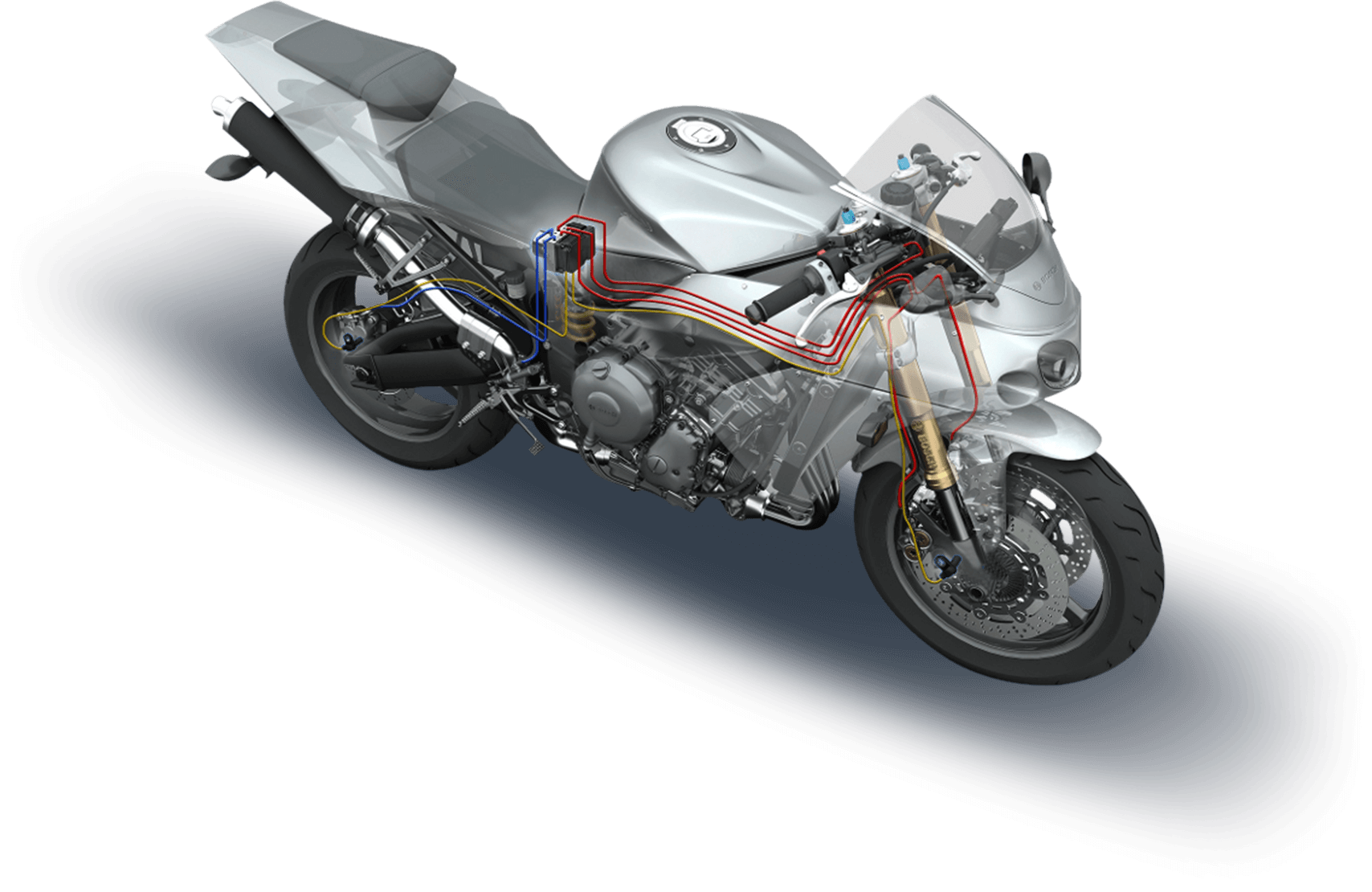

Our alloy steel forms the high-performance core for products that include Transmission Parts, Engine Components, Steering Innards, Bearings, High-Tensile Fasteners, etc in industries ranging from automobiles, manufacturing, energy & power generation, and more, owing to its unparalleled performance and inherent strength.

For decades, we have always been asked what makes our alloy steel unique. The answer is never a simple one.

We look at ourselves as not just an alloy steel maker but an integral component of global supply chains. A trusted partner for some of the largest companies and brands in the world, helping their business grow both in India and abroad through cutting-edge, tailor-made alloy steel products that are the fruit of a near-constant investment in R&D.

Read More

As one of only a handful of Indian steelmakers globally recognised as capable of producing international-grade alloy steel, we understand the role of the quality of our products that have helped us get to this point. As part of our efforts to continually deliver the highest quality alloy steel, our fully equipped in-house laboratory's focus is to research and develop products and processes that meet the continuously evolving standards of both our customers and the industry at large.

Have a unique requirement? Get in touch with us. We have

a steely resolve to help you find the product that best fits your needs, even if that means custom

building you one that does.

With significant investments in our capabilities, to keep pace with the growing demand, our Alloy Steel manufacturing facility produces over 400 grades & specifications of alloy steel, primarily in the automotive and engineering industries, for the manufacturing of speciality parts for engines, transmissions, steering, fasteners & bearings, fuel injections & braking systems, suspension systems, and more.

Read More

The alloy steel production methodology we employ at our facility has been fine-tuned and refined over years of

experimentation, innovation, and the adoption of internationally recognised best practices.

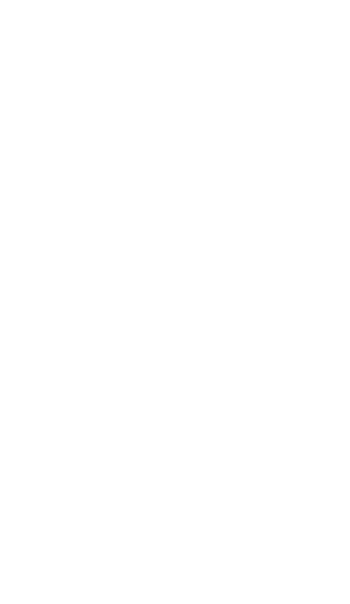

A scaled-down version of the modern Large Blast Furnace (LBF), the MBFs we

employ offer high degrees of efficiency and utilise the technologies that are the

norm in conventional LBFs.

Hot Waste Gases

Hot Waste Gases

Reduction of Iron Ore

Reduction of Iron Ore

Limestone Decomposes and Slag Forms

Limestone Decomposes and Slag Forms

Hot Air Blast

Hot Air Blast

Hot Waste Gases

Hot Waste Gases

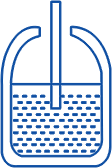

First developed in Brazil and successfully deployed in our production facility, the EOF allows our steelmaking operations to cope with challenges of raw material availability, capacity, and energy efficiency.

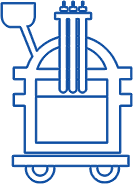

LRFs are a proven component of secondary metallurgy that allows us to improve the inherent quality of the liquid steel by compensating for thermal loss and refining the steel within the ladle itself.

The last stop in the production process before the steel is poured from the furnace into the Bloom and Billet Caster, the VDS removes all dissolved gases, thereby ensuring more ductile steel.

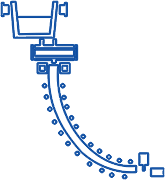

Energy and power saving, the Bloom and Billet Caster is a high-speed, automated, and sequential casting process that improves capacity utilisation and increases productivity.

It's a testament to our reputation that our products serve as integral components in some of the biggest brands and most well-known products across a wide array of industries. When complicated technologies require highly-engineered steel, Mukand is the company that makes it possible.

Have a unique requirement? Get in touch with us. We have a steely resolve to help you find the product that best fits your needs, even if that means custom building you one that does.